In the ever-evolving landscape of electronic components, the search for high-quality suppliers of Non-Waterproof Connectors has become a pivotal concern for global buyers. According to a recent report by MarketsandMarkets, the global connector market is projected to reach USD 80 billion by 2025, driven by the increasing demand for connectivity in various sectors such as automotive, telecommunications, and consumer electronics. Non-Waterproof Connectors, while often overshadowed by their waterproof counterparts, play a crucial role in everyday applications where moisture exposure is minimal. This blog aims to unveil the secrets of sourcing the best Non-Waterproof Connectors, highlighting key industry insights and providing strategies to identify reliable suppliers who meet stringent quality standards, ultimately ensuring optimal performance for diverse applications.

In various industries, the choice of connectors can significantly impact

efficiency and reliability.

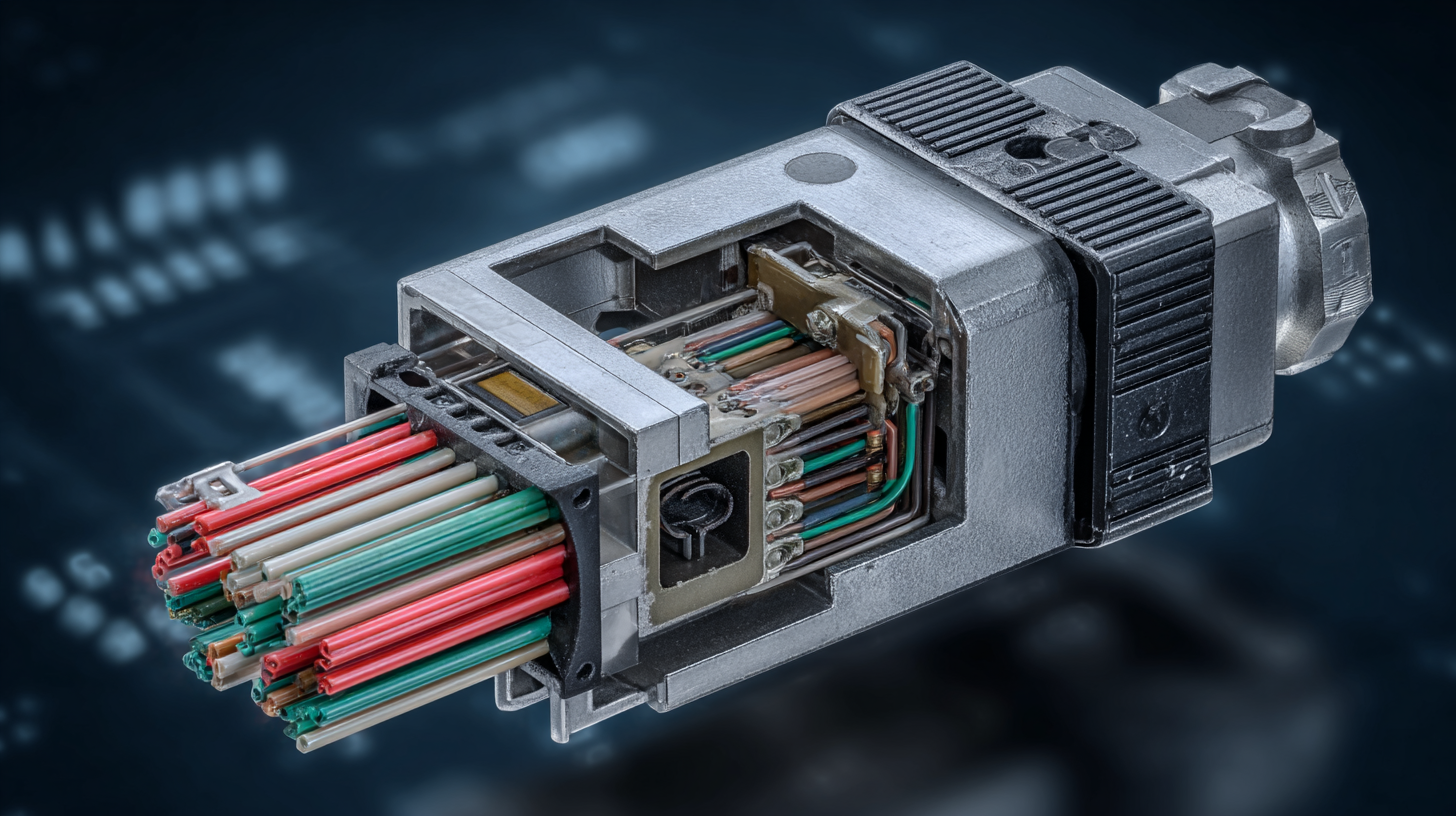

Non-waterproof connectors, while often overlooked, offer several key features that cater to specific applications.

These connectors are designed to excel in dry environments, providing a

cost-effective solution for many electronic devices.

They are lightweight, enabling easier installation and reducing the overall weight of systems, making them ideal for

consumer electronics and automotive applications.

Moreover, non-waterproof connectors typically feature simpler designs with fewer components, which not only reduces manufacturing costs but also simplifies troubleshooting and maintenance.

Their availability in a wide range of configurable options allows for customized solutions tailored to unique industry requirements.

From telecommunications to home appliances, understanding these strengths can empower global buyers to make informed decisions, ensuring optimal performance in their operational environments.

By prioritizing the right connector attributes, businesses can enhance their product durability and functionality without compromising on quality or budget.

Moreover, non-waterproof connectors typically feature simpler designs with fewer components, which not only reduces manufacturing costs but also simplifies troubleshooting and maintenance.

Their availability in a wide range of configurable options allows for customized solutions tailored to unique industry requirements.

From telecommunications to home appliances, understanding these strengths can empower global buyers to make informed decisions, ensuring optimal performance in their operational environments.

By prioritizing the right connector attributes, businesses can enhance their product durability and functionality without compromising on quality or budget.

The growing demand for non-waterproof connectors has become increasingly significant in various industries, particularly in the automotive and electronics sectors. According to a report by QY Research, the global market for non-waterproof connectors was valued at approximately $5.6 billion in 2022 and is expected to witness a compound annual growth rate (CAGR) of 4.8% through 2028. This uptick in demand can be attributed to the surge in electronic devices that require reliable connections but not necessarily in harsh environmental conditions.

In particular, the consumer electronics segment is driving much of the growth, with a notable increase in the production of smartphones and laptops. Statistics from MarketWatch indicated that over 1.5 billion smartphones were shipped globally in 2023, leading to a heightened requirement for non-waterproof connectors that can support various applications without compromising on performance. Moreover, as manufacturers continue to prioritize cost-effective materials, the shift towards using non-waterproof connectors is likely to persist, making them a focal point for global buyers looking to optimize their supply chains.

When it comes to indoor applications, non-waterproof connectors often outperform their waterproof counterparts, providing distinct advantages that cater to a variety of needs. One of the primary reasons for this is their enhanced ease of use. Non-waterproof connectors typically feature simpler designs and less stringent sealing requirements, which allows for quicker and more efficient installations. In settings like offices, homes, and indoor workshops, where exposure to moisture is minimal, these connectors offer a reliable and straightforward solution, reducing the hassle associated with more complex waterproof products.

Additionally, non-waterproof connectors are often more cost-effective while still delivering excellent performance. The manufacturing processes involved are generally less expensive, which translates to lower prices for consumers. This affordability does not compromise quality; instead, it allows users to invest in multiple connectors or upgrade their systems without breaking the bank. As a result, for indoor scenarios where durability against water exposure is not a priority, non-waterproof connectors become the go-to choice for both individuals and businesses looking to optimize their electrical connections efficiently and economically.

In the evolving landscape of industrial connectors, understanding the performance metrics of non-waterproof versus waterproof connectors is crucial for global buyers. Non-waterproof connectors are primarily designed for environments where moisture is not a concern, making them a popular choice in industries where cost-effectiveness and straightforward installations are paramount. Their lightweight design and ease of use can lead to lower manufacturing costs and faster deployment times. However, with the industrial connector market projected to exceed $8.7 billion in 2024 and grow at a CAGR of 2.8% through 2034, it’s essential to assess the durability and reliability of these connectors compared to their waterproof counterparts.

With the recent advancements in connector technology, such as the introduction of innovative waterproof connectors, users must weigh the advantages of both types based on specific applications. For instance, while waterproof connectors might incur higher initial costs, they offer enhanced protection against environmental factors, ensuring longevity in harsh conditions. As highlighted in upcoming trade events like the ICH 2025 Dongguan International Connector Exhibition, industry leaders will showcase the latest designs and performance metrics that will aid buyers in making informed decisions tailored to their operational needs. Understanding these dynamics will be vital for manufacturers and purchasers aiming to optimize their supply chains and enhance product reliability.

As technology continues to evolve, the demand for innovative non-waterproof connectors is on the rise. These connectors are playing an essential role in various industries, from consumer electronics to automotive applications. One of the most significant trends shaping the future of non-waterproof connector technology is the integration of smart features. Advanced materials and designs are being developed to enhance connectivity while minimizing bulk, making them more user-friendly and efficient. For instance, connectors with built-in sensors can monitor performance in real-time, providing valuable data that can help manufacturers optimize their products.

Another promising innovation is the shift towards modular connector systems. This flexibility allows for easier upgrades and replacements without needing to overhaul an entire setup. Such designs not only improve sustainability by extending the lifecycle of the connectors but also reduce costs for manufacturers and consumers alike. Additionally, the introduction of environmentally friendly materials in the production of non-waterproof connectors reflects a growing commitment to sustainability. With these advancements, the non-waterproof connector market is poised to become more dynamic, catering to the ever-changing needs of global buyers and setting new standards in technology and design.

Another promising innovation is the shift towards modular connector systems. This flexibility allows for easier upgrades and replacements without needing to overhaul an entire setup. Such designs not only improve sustainability by extending the lifecycle of the connectors but also reduce costs for manufacturers and consumers alike. Additionally, the introduction of environmentally friendly materials in the production of non-waterproof connectors reflects a growing commitment to sustainability. With these advancements, the non-waterproof connector market is poised to become more dynamic, catering to the ever-changing needs of global buyers and setting new standards in technology and design.